Environment

Environment Management

Guided by the Environmental Policy, we will comply with laws and regulations on the environment, along with building, maintaining, and continually improving our environmental management system. In addition to placing importance on product safety, we aim to keep environmental impact to a minimum in our product development by working to reduce the use of substances that negatively impact the environment and conserve resources and energy.

Based on our management philosophy of "Achieve Sustainability Management," Unipres Corporation contributes to environmental preservation from an international perspective by utilizing our excellence in press technology and providing environmentally friendly and safe products.

To pass down a beautiful and rich earth to the next generation, Unipres promotes the following activities.

1. We comply with environmental laws and regulations as well as other requirements to which our company agrees, and we work to protect the environment.

2. We endeavor to curb greenhouse gas emissions by bringing together materials, dies, equipment, and products on an entirely new plane.

3. We strive to prevent pollution of the air, water, and soil by reducing and limiting our use of environmentally hazardous substances (including harmful chemicals).

4. We endeavor to curb our use of mineral and water resources and our production of waste by conserving energy and resources, as well as reusing and recycling.

5. We collaborate with local communities and society at large to help preserve biodiversity and ecosystems.

6. We seek to maintain and upgrade our environmental management system by making ongoing improvements.

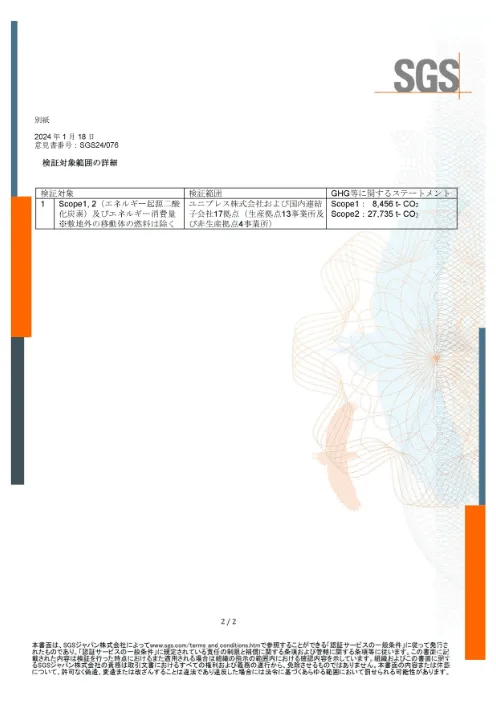

The Sustainability Committee deliberates on and determines environmental policies, targets, and action plans, including climate change countermeasures. Meanwhile, the Environment Committee, established under the Sustainability Committee, promotes related initiatives and regularly follows up on their progress on a quarterly basis.

Since 2004, the Unipres Group has been working on the acquisition of ISO 14001 certification, an international standard for environmental management systems. We are making progress in our efforts to reduce the environmental impact of our corporate activities through implementing the environmental management system. Across the entire Unipres Group, 91.3% of business sites (based on the number of manufacturing sites) were certified as of fiscal 2024.

Climate Change Countermeasures

Targets and results can be found hereHaving identified climate change countermeasures as one of its material issues, the Unipres Group will work to mitigate the effects of climate change by reducing its greenhouse gas emissions, identified as the principal cause of climate change, across the Group. Specific measures include introducing highly efficient equipment, reviewing manufacturing methods, and switching to renewable energy sources.

Unipres Group expressed its support for the TCFD in June 2021. By promoting information disclosure based on the TCFD recommendations, we will build a sustainable management foundation that includes trusting relationships with stakeholders.

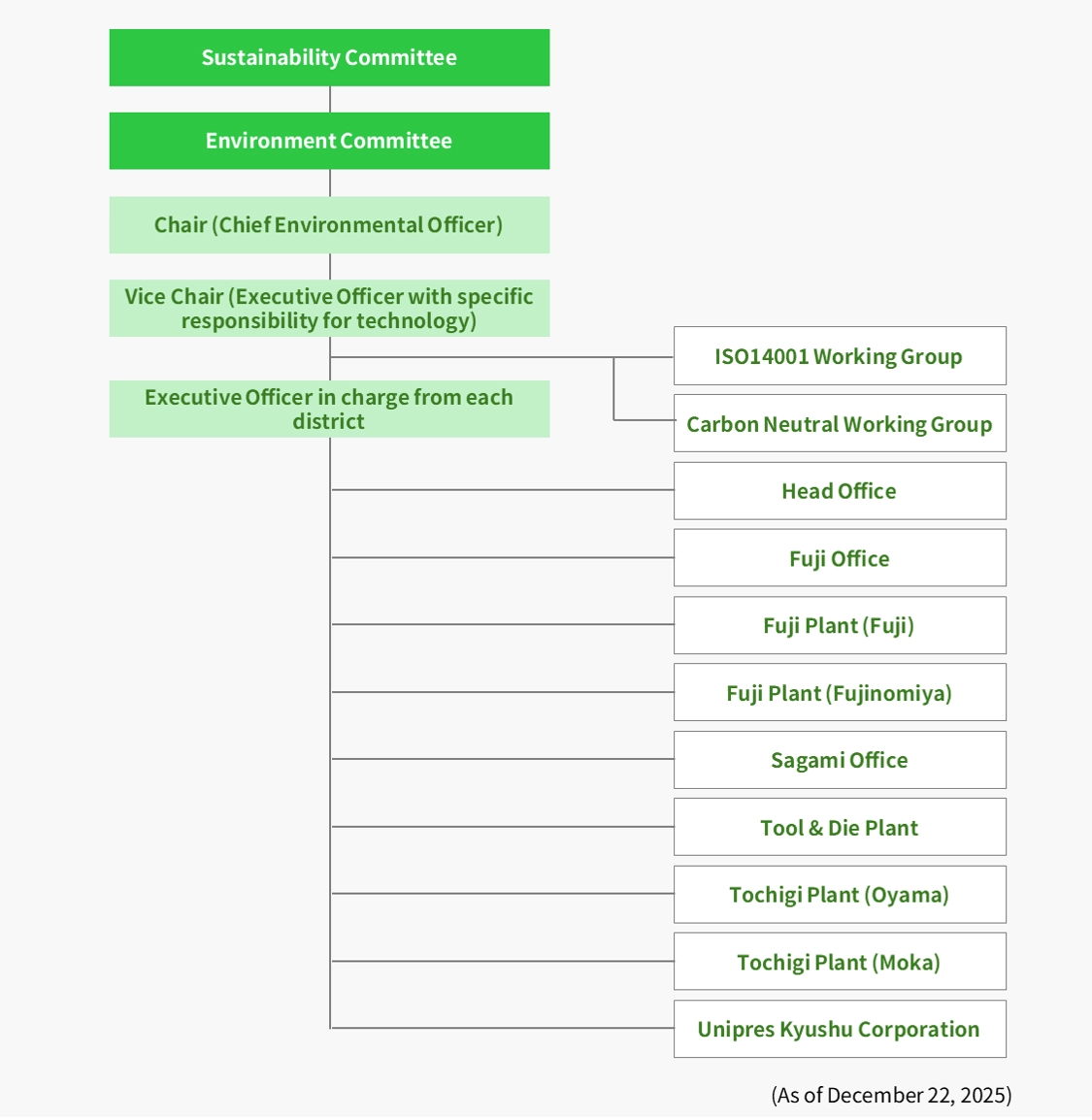

We have set greenhouse gas emission reduction targets toward achieving carbon neutrality.

[Greenhouse Gas (GHG) Emission Reduction Targets]

FY2030: 50% reduction in GHG emissions from business activities (compared to FY2018)FY2050: Net zero GHG emissions from business activities

(FY2050 Challenge)

Addressing net zero GHG emissions together with suppliers

Implementing Internal Carbon Pricing

The Unipres Group began implementing an internal carbon pricing system in 2023. The system will be widely implemented in management decisions, mainly for use in investment decisions on investing in equipment that will contribute to climate change countermeasures.

[Overview of the Unipres Group's ICP System]

- Internal carbon price: 18,000 yen/t-CO2

- Scope: Equipment investments involving changes in greenhouse gas emissions

- Application method: Apply the internal carbon price to convert the increase or decrease in CO2 emissions resulting from the applicable equipment investment plan into a monetary value, and use this value as a reference for investment decisions

Switching to Electricity Derived from Renewable Energy Sources

The Unipres Group has switched to photovoltaic- and wind power-derived electric power free of CO₂ emissions for 100% of electric power used at nine sites: Sagami Office, Tochigi Plants (Oyama and Moka), Fuji Plants (Fuji and Fujinomiya), Unipres Mold (Hiroshima and Moka), Unipres Butsuryu (Gotemba), and Unipres (UK). Additionally, measures are being taken to switch some of the electric power used at Unipres Mold (Fuji), Unipres Precision, and Unipres India to electric power derived from renewable energy sources. We will continue to promote this initiative throughout the entire Group and further introduce renewable energy at our domestic and overseas sites.

Installing Photovoltaic Power Systems

The Unipres Group has promoted the installation of photovoltaic power systems since 2012. At present, we have installed the system at four sites in Japan; our Tochigi plants at Oyama and Moka and Fuji plants at Fuji and Fujinomiya, along with six sites overseas in Mexico, the UK, China (Unipres Guangzhou, Unipres Precision Guangzhou, Unipres Zhengzhou), and Indonesia, thereby contributing to reducing greenhouse gas emissions.

Switching to Fuels with Low Greenhouse Gas Emissions

Unipres (UK) is promoting the use of the bio-fuel HVO100 (hydrotreated vegetable oil) in its efforts to curb environmental impact. In 2022, the company converted six of its seven diesel-powered vehicles to biofuel vehicles. With biofuel vehicles, it is possible to reduce greenhouse gas emissions by 90% compared to standard diesel fossil fuel.

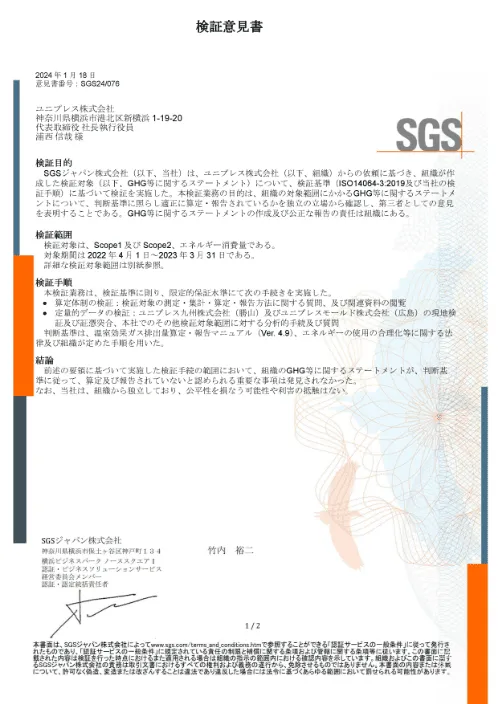

Third-Party Verification

Unipres Group undergoes third-party verification by SGS Japan Inc. to ensure the reliability of the environmental data. The verification evaluates the validity of the data collection, aggregation, and calculation processes, and is part of our efforts to improve the reliability of our data.

Green Product Development

Targets and results can be found hereThe advancement and spread of electrification requires the development of technologies for creating even lighter and stronger auto bodies. In response, we are focusing on strategic technological development to realize weight reduction, such as ultra-high-tensile materials, hot stamping, and technologies to support the shift to using aluminum. This enables us to achieve both safety and environmental performance. Moreover, we are working on entering the electric vehicle powertrain parts market by taking advantage of our precision press technology.

Efficient Use of Resources

Targets and results can be found hereThe Unipres Group considers the effective use of limited resources as a material issue for realizing a sustainable society. We are curbing the use of mineral and water resources and reducing waste by promoting the conservation of energy and resources, as well as reusing and recycling, based on our Environmental Policy.

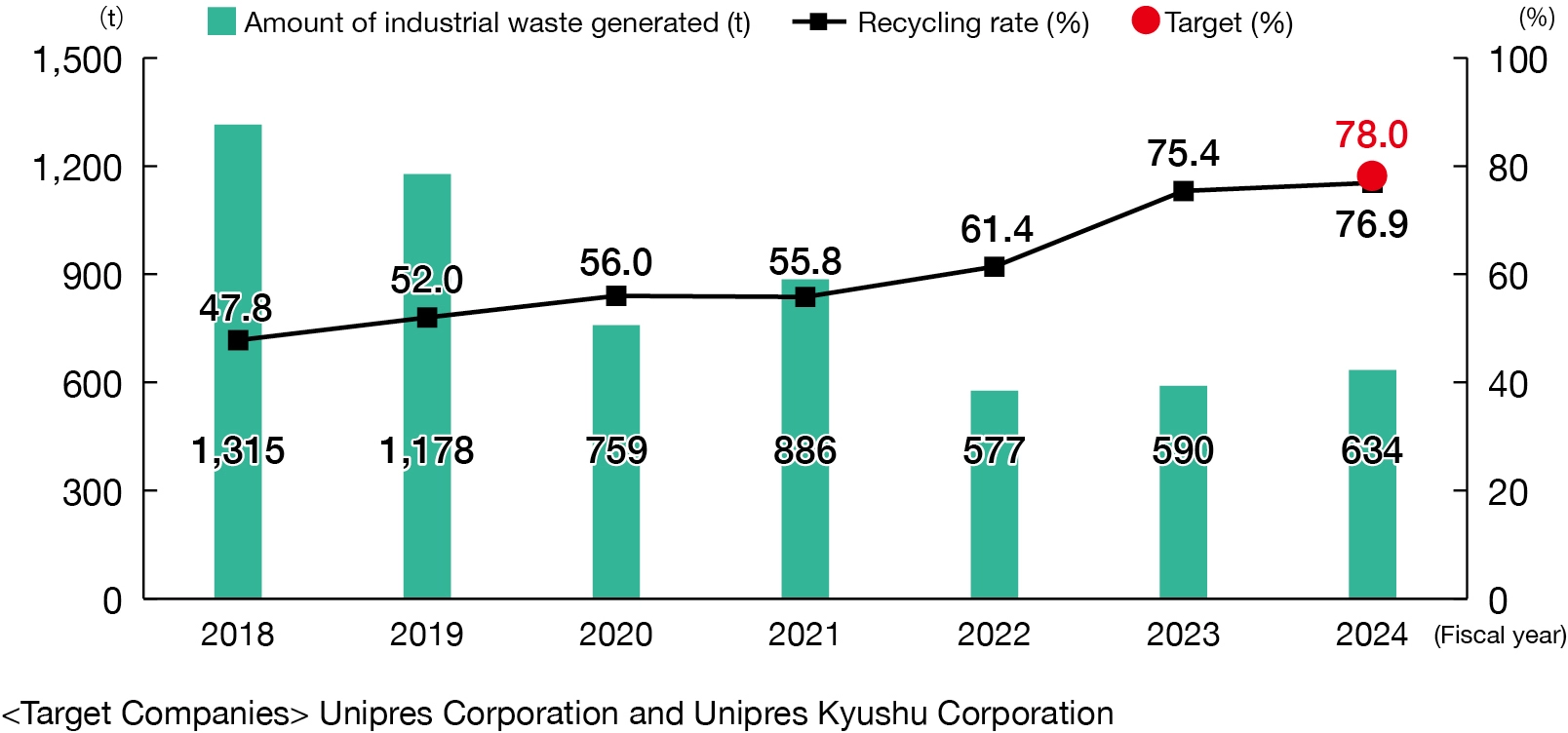

Activities for Improving the Industrial Waste Recycling Rate

Steel materials, which make up more than 90% of the industrial waste we emit, are increasingly being recycled, and there is already a stable recycling system for these materials. Therefore, our target recycling rate is intentionally set for industrial waste excluding steel materials, and the target is set at a more ambitious level.

Change in Volume of Industrial Waste Emissions and Recycling Rate

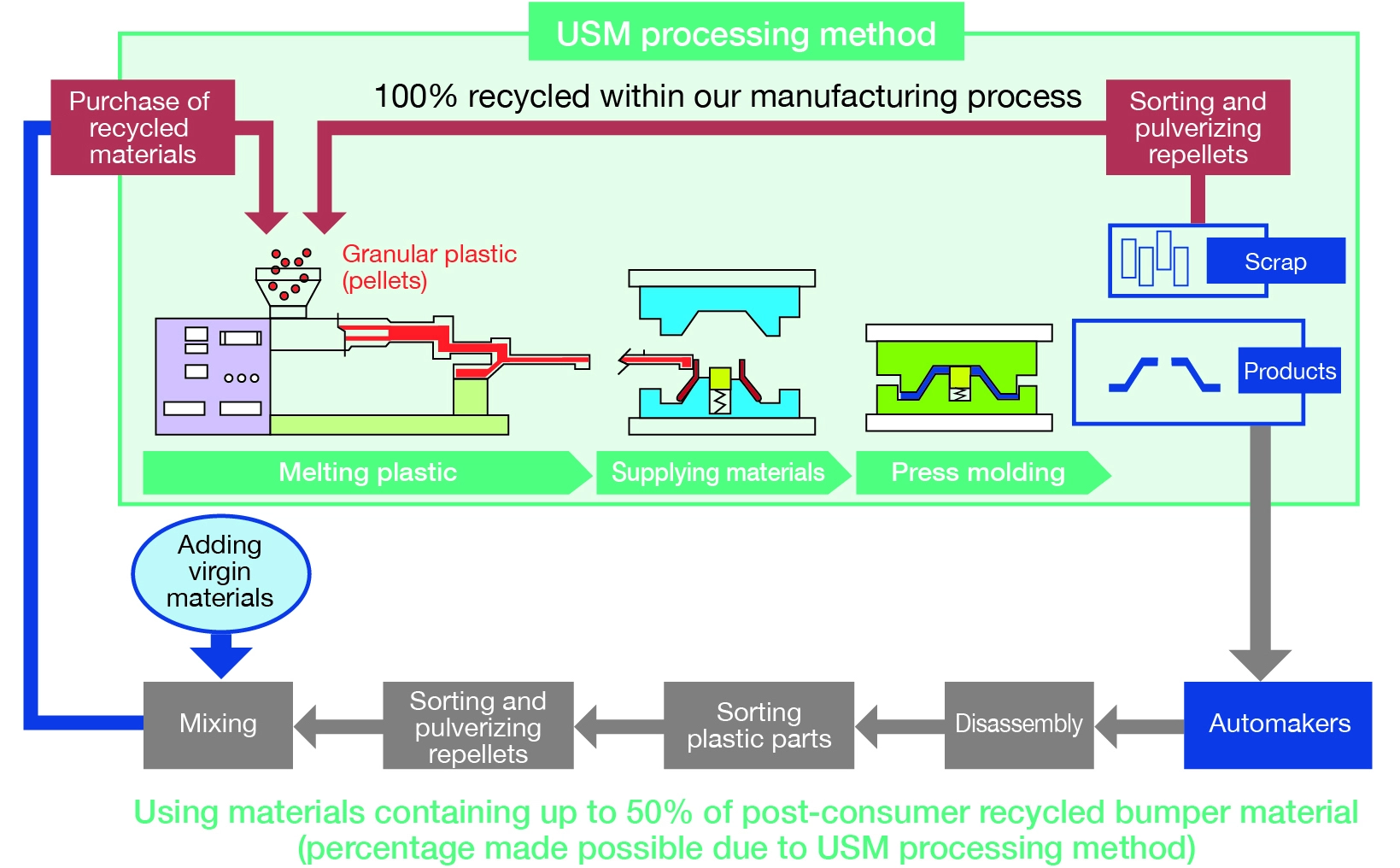

Recycling Plastic Materials

In the plastics business, we have established a recycling system utilizing Unipres processing methods (the USM processing method*). In cooperation with car manufacturers, we use recycled materials in our resin pressed parts, containing up to 50% recycled bumper material collected from the market. In addition, we reuse 100% of the scrap from resin pressed products generated during the production process using the USM processing method in-house. The use of these recycled materials allows us to contribute to protecting the environment, while at the same time helping us reduce the costs of parts, thereby enabling us to offer more competitively priced products.

*The USM (Unipres stamping molding) processing method is a technology for pouring molten plastic into a die for press molding.

Environmental Pollution Measures

Targets and results can be found hereEnvironmental pollutants and chemicals used in products or generated during manufacturing may adversely affect human health or biodiversity. The Unipres Group will therefore fulfill its responsibility to society by reducing and restricting the use of substances that negatively impact the environment (including harmful chemicals) and preventing air, water, and soil pollution in accordance with its Environmental Policy.

Protecting Air and Water Quality

Unipres has been working toward its medium to long-term target of zero regulatory standard violations related to air or water pollution. In fiscal 2024, we committed zero regulatory standard violations across Japan.

Initiatives for Substances of High Concern

With the understanding and cooperation of its suppliers, Unipres keeps track of whether the materials it uses contain substances that negatively impact the environment, including substances of high concern, and reports on this matter to customers. Moreover, in order to respond quickly and appropriately to tightening regulations on chemical substances in each country, including PRTR regulations, domestic chemical substance-related laws, European ELV Directives, and REACH regulations, the Environment Committee shares information and considers countermeasures as needed.

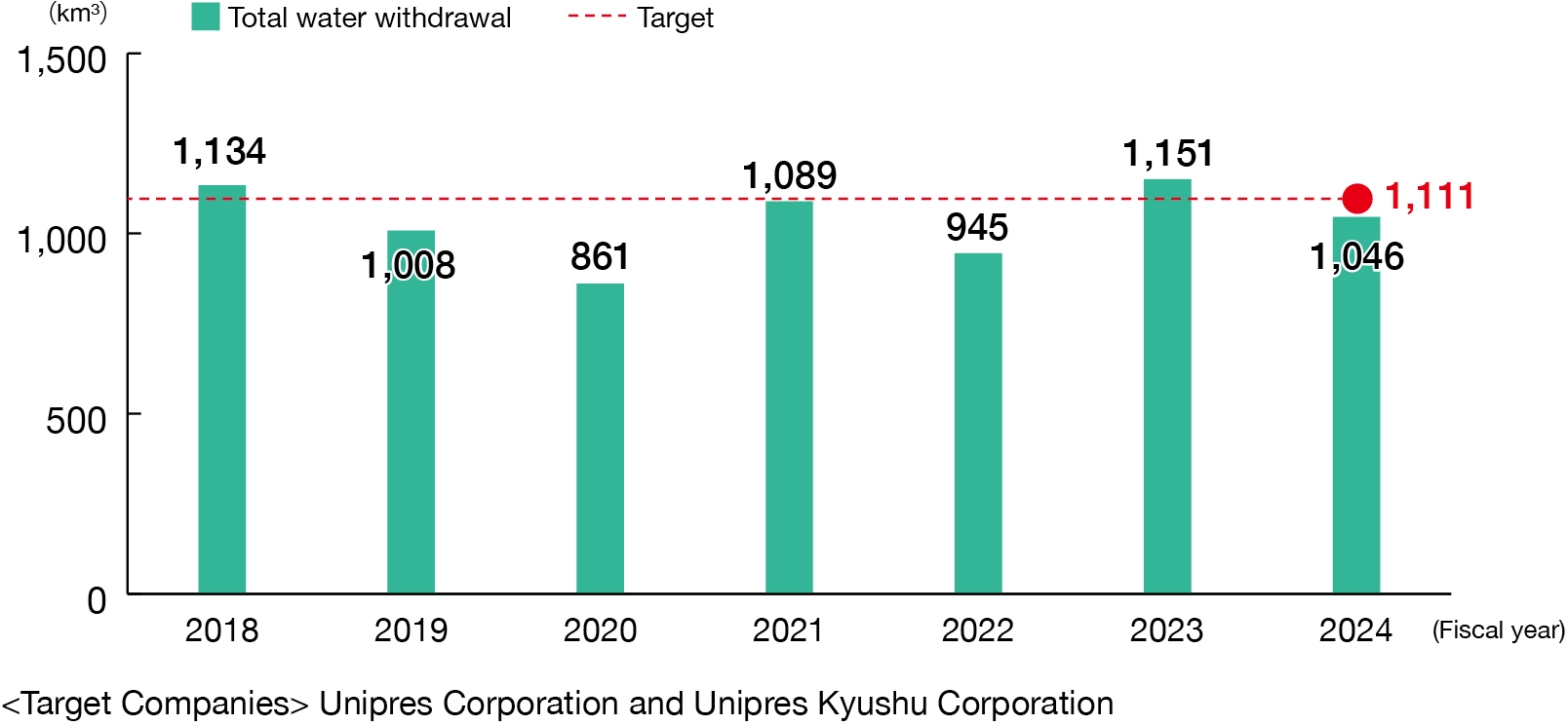

Water Resource Conservation

Targets and results can be found hereRecognizing that water resources are not only essential for the continuation of our business, but also important to the residents of the communities where we operate, we are committed to reducing water usage and environmental impact.

Each business office strives to use water resources effectively by circulating and reappropriating cooling water, along with patrolling sites to check for water leakages.

Change in Total Water Withdrawal in Japan

Conservation of Biodiversity

Targets and results can be found hereWhile the Unipres Group receives numerous benefits from various ecosystems, it also adversely impacts biodiversity through its business activities. Therefore, in addition to preventing environmental pollution, reducing greenhouse gas emissions, and other climate change countermeasures, we contribute to conserving biodiversity through bio-conservation activities in collaboration with local communities as part of our social contribution initiatives.

Forest Restoration Partnership System/Unipres Forest

We have endorsed Kanagawa Prefecture's Forest Restoration Partnership System since July 2024. This activity supports the conservation of unmaintained forests within designated areas, and links to the creation of diverse forest systems, thereby ensuring habitats optimized for a wider range of organisms.

Installation of Beehives

The honeybee population is in decline in France, where UM Corporation, SAS is located. We partnered with a local beekeeper to install four beehives on the premises, thereby creating a new habitat for honeybees.