Vision for the future 03

Aiming for a sustainable future.

Vision for the future

Reason

Issue

Solution

Unipres is promoting activities aimed at achieving sustainability in every phase of its operations.

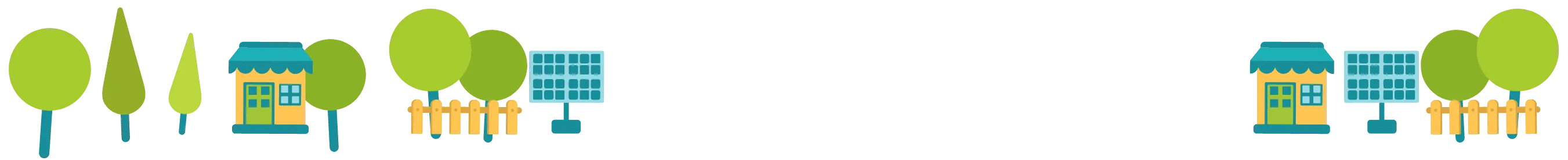

For cleaner energy

We are promoting the use of renewable energy, the switching of energy sources, and energy conservation simultaneously, and are implementing an internal carbon pricing system* to encourage related capital investments.

*This system virtually translates CO2 emissions into costs, and this is used as a basis for our capital investment decisions.

Company-wide recycling of industrial waste

Auto body parts and transmission parts manufactured by Unipres are mostly made of steel. Steel scrap from the manufacturing process is recycled to be used as materials for iron products.

Furthermore, efforts are being enhanced to improve the recycling rate for industrial waste other than steel scrap, including setting targets for each plant. The recycling rate for fiscal 2024 exceeded 70%.

Implementing a modal shift in logistics

We are transitioning from truck-based transportation to freight trains and ferries. By utilizing advanced production and inventory management, we are simultaneously reducing both CO2 emissions and transportation costs.

Recycling plastic press scrap from plants

Our plastic press business uses materials containing up to 50% of post-consumer recycled bumper material. In addition, 100% of scrap generated during a production process is recycled internally.

Other visions for the future