Product Information

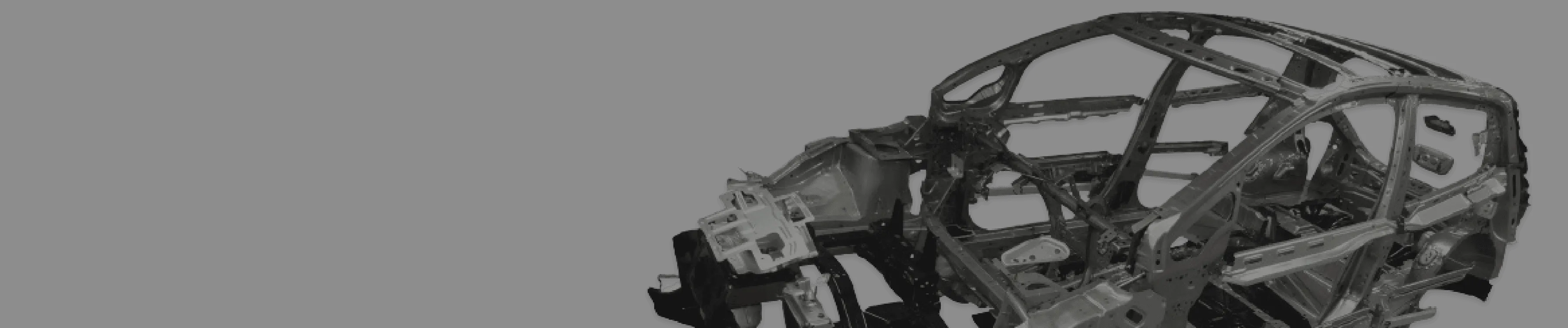

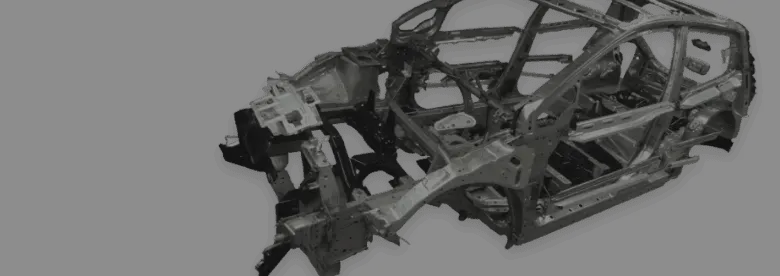

Parts for vehicle collision safety

Body frame components require high collision safety performance and weight reduction. To address these two conflicting demands, we use high-tensile forming technology and hot stamping processing methods to produce optimal parts.

-

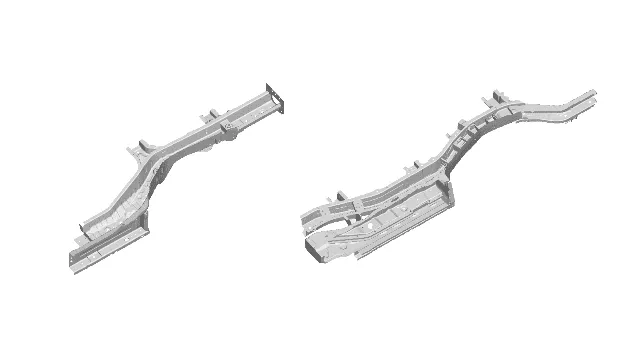

Front side member

Running longitudinally from the front of the car body to the passenger compartment, this single part must have varying strengths in the event of a frontal collision. While the front portion deforms easily to absorb the energy from impact, the rear portion does not deform to protect occupants. We use ultra-high-tensile materials and hot stamping processing methods to achieve various shapes and required strengths.

Thin sheets are also used to reduce the weight and contribute to improving fuel performance. -

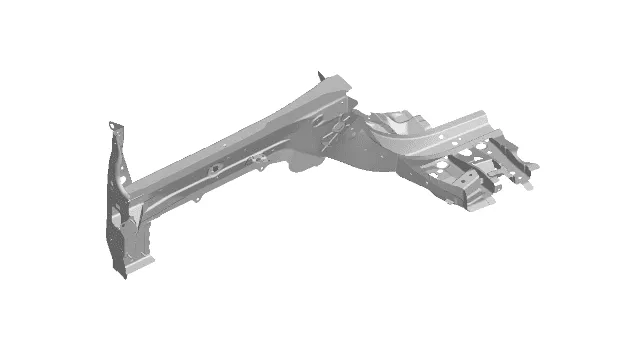

Rear side member

This part runs longitudinally from the rear of the car body to the passenger compartment. To ensure adequate trunk storage space, it has a complex shape and is difficult to form. Furthermore, exceptionally high strength is required to protect occupants in the event of a rear collision. We use ultra-high-tensile materials and hot stamping processing methods to create complex shapes while still achieving high strength.

-

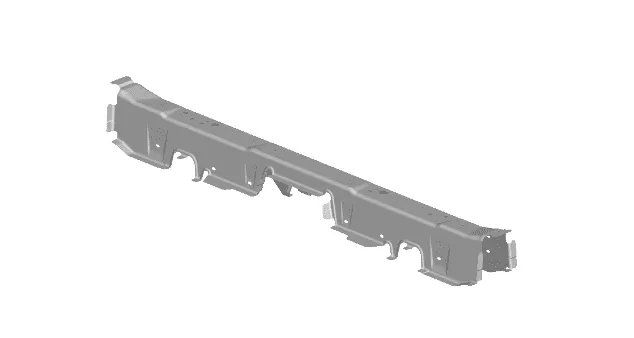

Cross member

A part that connects the left and right sides of an automobile.

It is almost the same length as the width of the car body. Exceptionally high strength is required to prevent deformation and protect occupants, even in the event of impact from a side collision. We achieve both the necessary strength and weight reduction by combining ultra-high-tensile materials and steel materials with different specifications, along with using technologies such as hot stamping and tempering processing methods to create varying strengths. -

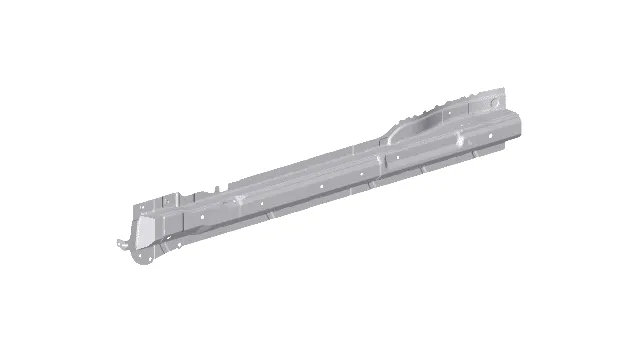

Side sill

This long part is mounted beneath the door. In the event of a side collision, strong impact will be applied directly to the side sill.

Therefore, we use ultra-high-tensile materials to achieve exceptionally high strength. -

Front pillar

A part that supports the windshield. It requires high strength to protect occupants in the event of a frontal collision.

-

Center pillar

A part that connects the upper and lower sections of an automobile. Located between the front and rear seats, it supports the passenger compartment. In the event of a side collision, strong impact will be applied directly to the center pillar.

Therefore, portions are designed to deform easily to absorb the energy from impact, while other portions are reinforced to prevent deformation to protect occupants.

We satisfy the required advanced forming and welding techniques by using high-tensile materials, hot stamping and patchwork processing methods, among other technologies. -

Side roof rail

A part that forms a car's roof frame. Exceptionally high strength is required to prevent deformation and protect occupants in the event of a side collision or rollover. We use ultra-high-tensile materials and hot stamping processing methods to achieve the necessary strength.

-

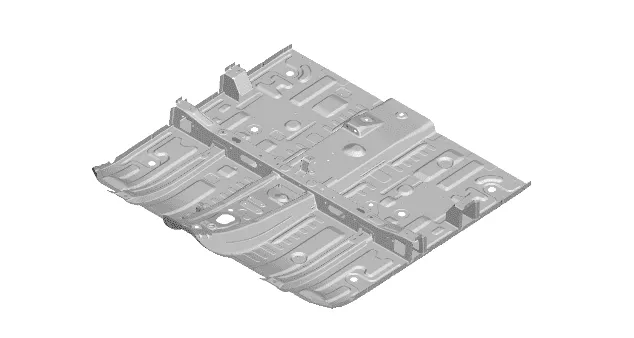

Front floor panel

A part that forms the floor of the passenger compartment. Exceptionally high strength is required to minimize floor deformation and protect occupants in the event of a frontal collision. We meet the performance requirements by using ultra-high-tensile materials, along with advanced forming, assembly, and other technologies.

-

Steering member

A part that supports components such as the steering wheel. High car body rigidity is required to ensure stable driving during high-speed lane changes and turns, in addition to basic automobile functions like driving, turning, and stopping.

-

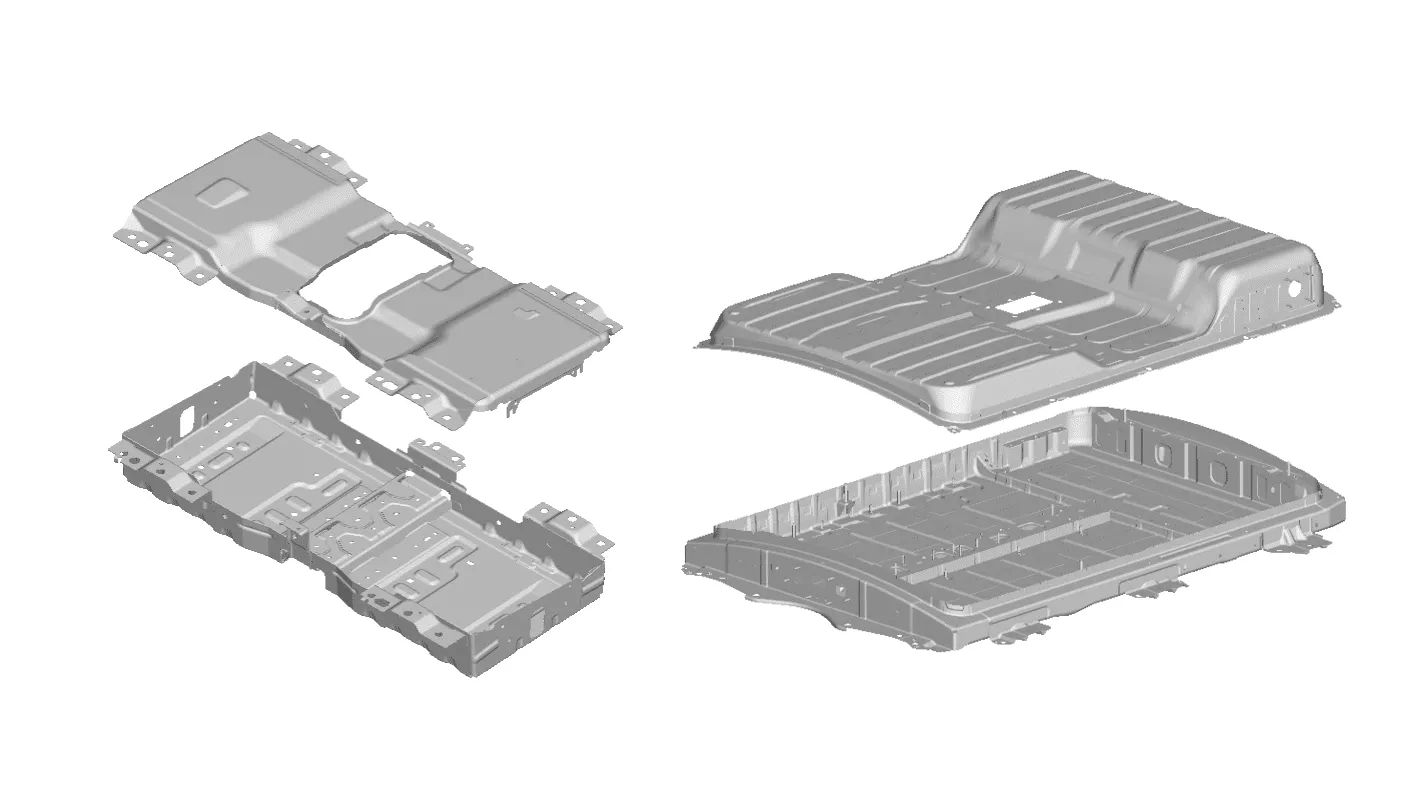

Fuel tank

A part that stores fuels, such as gasoline. Advanced deep drawing press forming and joining technologies are required to ensure maximum capacity in a limited space.

-

Filler tube

A pipe-like component that connects the fuel inlet to the fuel tank. It has a complex shape to ensure smooth fueling and requires high airtightness. We meet these requirements using advanced processing technology.

-

Battery case

This is the case for the battery that powers electric vehicles. It is located under the vehicle. Airtightness is critical to protect the battery in various environments. Additionally, as electric vehicles are heavier because of the battery, they sustain greater impact in a collision. High strength is needed to ensure that the impact from a collision does not affect the battery. At the same time, weight reduction is necessary to mitigate impact from a collision, making this a part that requires sophisticated technologies. We use high-tensile materials and advanced joining technologies to meet these conflicting requirements.