Product Information

Be they torque converters and transmissions that transfer power from the engine, or components unique to electric vehicles, all parts require a high level of precision.

Unipres utilizes the precision press technology it has developed to form these components.

-

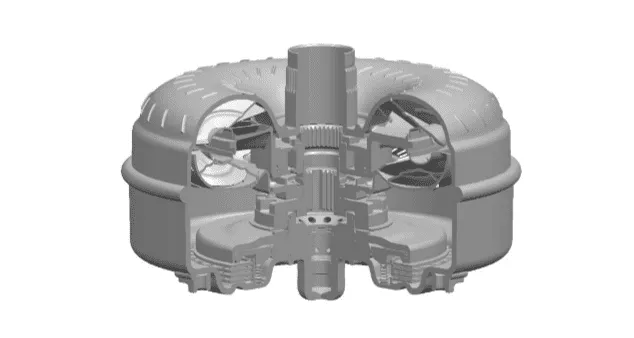

Torque converter

A part that transfers an engine's power to the transmission.

It is an essential component for achieving a smooth start and acceleration, low fuel consumption, and low noise in high-output, large-displacement engines.

We have developed and productized torque converters with the best fluid and lock-up performance to meet these requirements. -

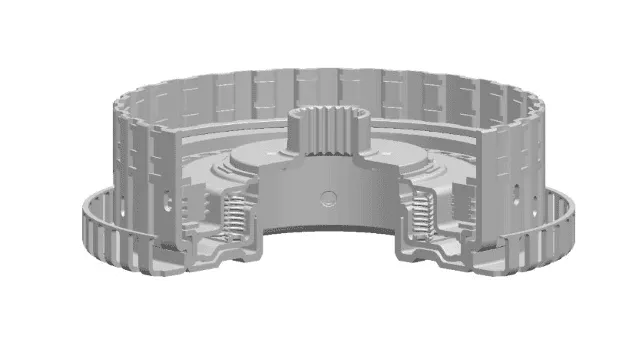

Clutch pack

A multi-plate clutch for an automatic transmission. We have developed and productized a clutch pack that meets the required strength and performance and is still compact.

-

Clutch drum

A processing component with a smooth outer surface and internal gear teeth (high-precision gear teeth on the inside only) mounted in plug-in hybrid vehicles. We have achieved both low cost and high quality using pressing.

-

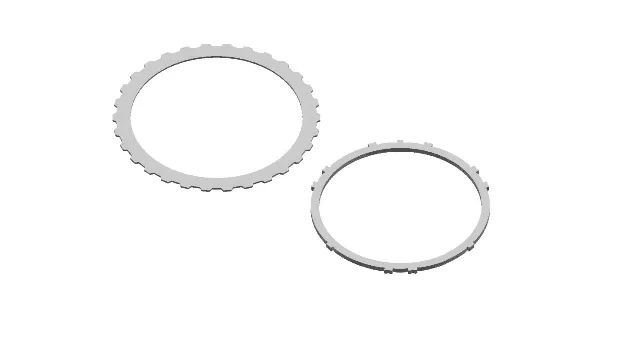

Driven plate / Retaining plate

Parts that make up a clutch pack. A high degree of planarity and high-precision surface finish and sheet thickness are required to reliably transmit power by friction. We meet all of these requirements using a fine blanking processing method for pressing.

-

Part for cooling EV motors

This is a water channel cover for cooling the motor of plug-in hybrid vehicles.Exceptional sealing performance is necessary to prevent water from leaking. We have minimized press variations and used laser welding to join the piping to curved sections.

-

Piston plunger

A part used for transmission shifts in a continuously variable transmission (CVT).

Using advanced press technology (near-net shape technology) that can alter the sheet's thickness by section, we have created a high-rigidity, low-cost part for both strength and weight reduction. -

Carrier pack

A part for the planetary gear mechanism required for switching between forward and reverse in an automatic transmission. By combining such technologies as micron-level machining and electron beam welding technology, we have achieved the necessary high precision.

-

Carrier plate / base

A component part of a planetary gear mechanism. Although the part has large cutouts and low rigidity, we have achieved the required high precision by selecting optimal cutting conditions.

-

End plate

A component of a hybrid system motor. We have enabled highly precise press forming of aluminum material, which is considered difficult to punch.

-

Oil pan

A part for retaining transmission oil. By deep drawing thin sheets, we have succeeded in creating a high-quality, low-cost part.