Innovative technology

for products

with high added value

Plastic Press Products

-

Weight Reduction

We contribute to weight reduction by replacing steel and aluminum with plastic materials. Using our plastic press forming technology,

we are developing plastic battery cases and inverter covers with added features, such as flame retardancy and electromagnetic shielding. -

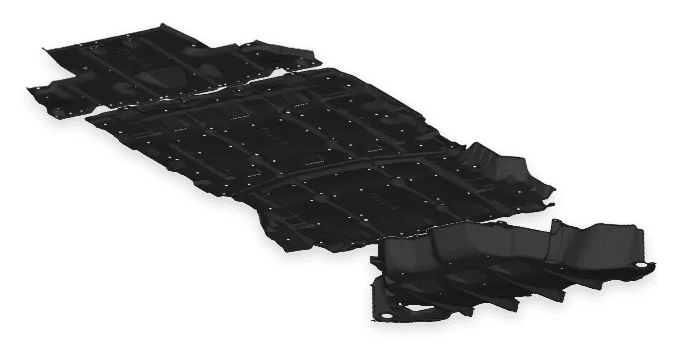

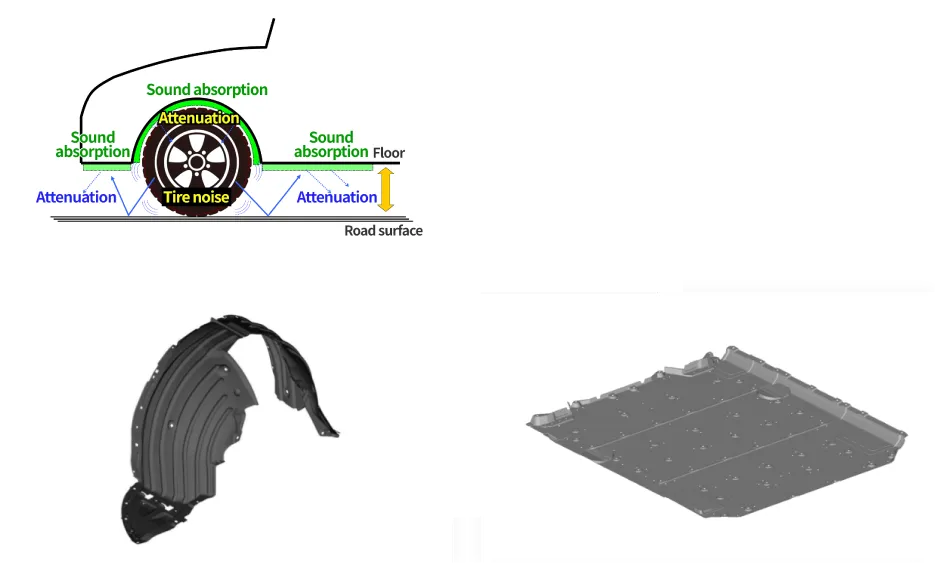

Adapting to Electric Vehicles

(Improving the performance of aerodynamics, noise reduction, and vibration control)Improving the aerodynamic performance of a vehicle contributes significantly to improving its fuel and energy efficiency. We are thus working to develop large, integrated, and flat floor covers. Furthermore, due to advances in electrification, the cause of in-cabin noise has changed from engine noise to tire-induced road noise, rapidly increasing the demand for improved noise reduction and vibration control performance. To enhance quietness, we are developing products including protector fender covers and floor covers with sound-absorbing and noise-reducing capabilities to minimize road noise.

-

Environmental Considerations

We are using our plastic press technology to develop environmentally friendly products, including products made with sustainable materials such as cellulose nanofiber (CNF) fillers and bio-based plastic materials, along with increasing the use of recycled materials.